Last month, Porsche flew me to Düsseldorf for the Porsche Cayenne Technology Workshop, where engineers in classrooms taught me detailed technical minutiae about what’s good on the new 2019 Porsche Cayenne. The whole thing was extremely German, and that’s a very good thing. Here’s what I learned.

Porsche’s money maker, the Cayenne, is all new for 2019, and the brand wants to make sure everyone knows what makes it different from the outgoing model. That’s why Porsche held a technical workshop at the ADAC Fahrsicherheitszentrum (driving safety center) in Grevenbroich, just outside of Düsseldorf.

Shortly after arriving, journalists broke off into groups, each of which was assigned to a classroom where an engineer stood at the front of the room and lectured about the Cayenne’s chassis, electrical system, powertrain or body. Here are the interesting bits I learned in those four “classes.”

48-Volt Electrically Controlled Sway Bars

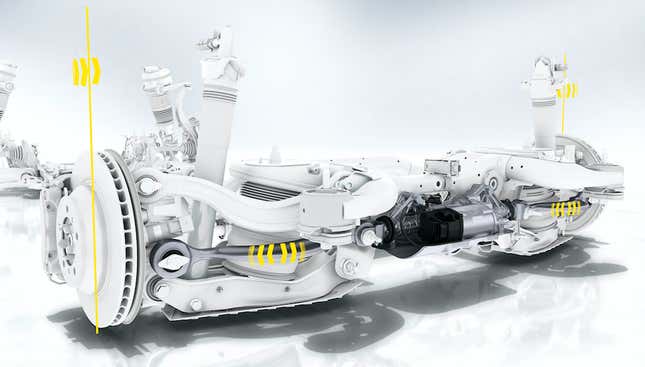

In the video here, you can see the Cayenne’s new front suspension setup. Built on an aluminum subframe instead of a steel one like on the current model, the double-wishbone suspension is gone, having been replaced by a multi-link design. Porsche also says the rubber bushings that once connected the subframe are gone, and have instead been replaced by “integrated” ones, which apparently helps stiffen the structure for better response.

What Christoph Bittner, steering systems manager for the new Cayenne, is showing me in the clip above is what Porsche calls Porsche Dynamic Chassis Control active roll stabilization.

The last generation Porsche Cayenne had a similar system, but it was electro hydraulically-actuated and sapped power from the engine at all times thanks to the always-on pump. Plus, it took a bit of time to react.

But for 2019, the Cayenne gets a dedicated 48 volt system whose sole job it is to manage body roll through the electromechanical roll stabilization system. The way it works, as Bittner shows me, is it uses a motor and a three-stage planetary gear reduction to rotate one half of the anti-roll bar relative to the other. Both of these halves, which are rather stiff compared to a conventional sway bar, are mounted to the stationary subframe near the center, and at the end to a link that hooks to the car’s moving suspension arm.

During body roll (which is detected by a number of onboard sensors), one side’s control arm wants to move up (relative to the subframe) more than the other control arm does; to prevent this, the active roll stabilization essentially uses the other half of the sway bar to pull up the control arm on the other side, which yanks the body body down flat.

The system, Porsche claims, is capable of producing 885 lb-ft of torque to twist the two parts of the sway bar against one another in turns. This means that the tall (but shorter than the current model) Cayenne can corner flat all the way up to 0.8G of lateral acceleration. It can, according to Bittner, even compensate for tire deformation to ensure true flatness.

And, in cases where you don’t want the suspension to remain perfectly flat—like when you want to cruise around with maximum ride comfort, or when you’re off-road and want your tires touching the ground at all times—the system can allow wheel articulation by reducing its torque output.

Three-Chamber Air Suspension

Another cool bit of tech Porsche had on display was its three-chamber air suspension, which essentially blocks off certain cells inside the shock with the push of a button. By lowering the total system volume, the spring rate increases (which you might want for track driving), and by opening the valves and maximizing the total chamber volume, spring rates decrease for smooth highway cruising.

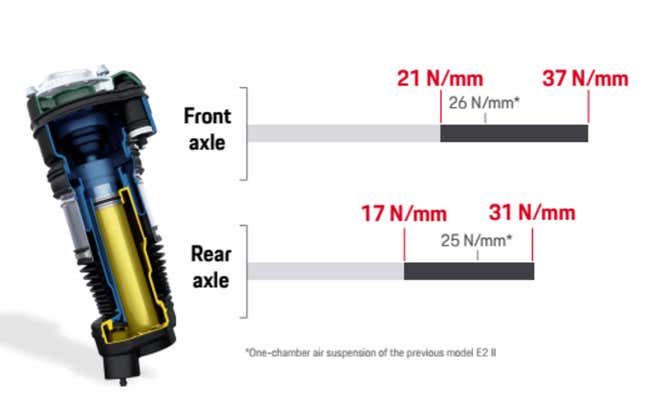

Having three chambers instead of one or two means drivers get a bit more granularity in tuning their suspension stiffness. Here’s a look at the new Cayenne’s range of spring rates compared to the single stiffness offered by the current generation Cayenne’s single chamber system (a two chamber system is also offered on the current model—that’s not shown for reasons unknown):

And here’s a nice breakdown of how the Panamera’s three-chamber air suspension system (similar to the one used on the new Cayenne) uses valves to vary the spring’s volume, and thus the spring pressure (which is proportional to spring rate):

The spring rates, Porsche says, can be adjusted manually via buttons on the center console, or they can adjust automatically if the car senses “strong pitching or rolling motion.” In addition to the adjustable spring rates, the air suspension offers the aerodynamic and off-road advantages of having six different ride height settings varying between 6.3 inches and 9.6 inches.

Rear Steering

The next thing I found interesting was the way the Cayenne’s rear steering system works. Similar to the setup in the 911 and Panamera, the setup simply replaces one of the inner suspension mounting points on each side with a translating mount.

That mount moves a maximum of 13 millimeters in either direction as an electric motor uses a belt drive (which acts to multiply the motor’s torque) to rotate a trapezoidal screw rack (which also provides a mechanical advantage, as it’s a power screw—a bit different than ball screw style electric power steering racks common in electric power steering systems). That rack is what moves the mounting point, which pushes and pulls the suspension link, which creates a torque on the rear knuckle.

What makes it especially intriguing to me is just how few unique parts the rear steering system uses. Instead of incorporating ball joints and tie rod ends like you’d see on a standard front steering setup (this is what older rear-steer GM trucks and rear-steer Preludes did), the Cayenne—similar to its Q7 sibling—simply uses the regular bushings as pivots.

In other words, all the rear-steer setup on the Cayenne does is replace one of the suspension link’s inner mounting points with a motor-driven mounting point that can translate laterally. The end result is up to three degrees of rear steering angle thanks solely to the compliance of rubber bushings.

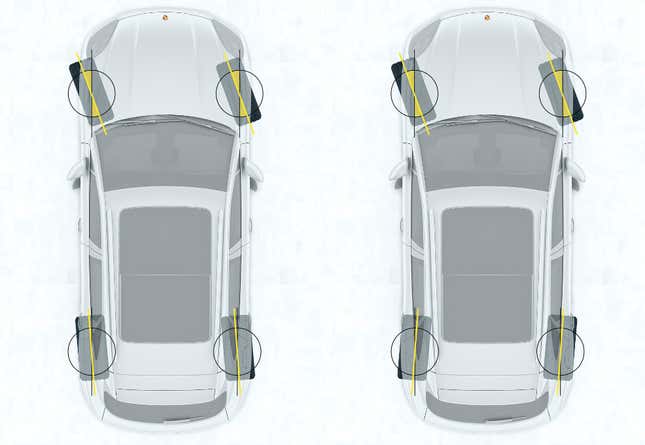

As far as user-benefit, rear axle steering reduces the car’s turning diameter by two feet. It can do this because, at speeds under 50 mph, the front and rear wheels steer in opposite directions. The fronts turn where the car’s nose wants to go, and the rears make sure the back end tucks in neatly behind that nose in the direction of intended travel.

That low speed example is shown on the right in the image above. At speeds higher than 50 mph, though, the rear wheels turn in the same direction as the fronts, so as to help “shift” the car in one direction smoothly, and ensure stability on the highway.

Porsche Surface Coated Brake

Porsche was excited to show off its “innovative new braking technology” called the Porsche Surface Coated Brake, or PSCB. Essentially, it’s meant to be an in-between option for folks who want something a bit more special than standard steel discs, but who don’t want to drop nine grand on carbon ceramics.

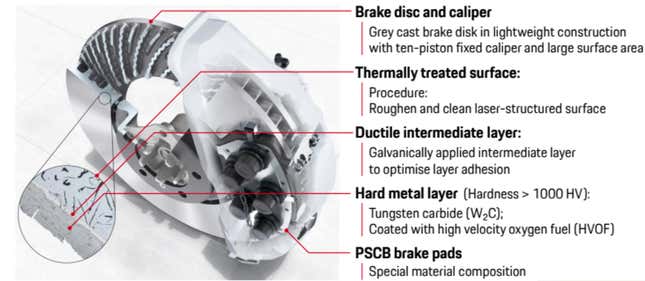

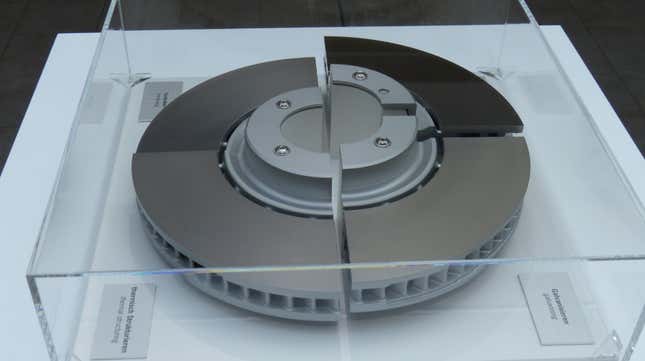

In essence, PSCB takes a standard steel rotor (with aluminum center “hat”) and uses a high velocity oxygen fuel coating process to bake a 100 micron-thin layer of extremely hard (100 in the Vickers hardness scale) layer of tungsten-carbide to the surface.

That hard surface, Porsche says, results in a tenfold reduction in brake dust, much of which the company says is normally caused by rotor wear, not just pad wear as most people think.

This special rotor required Porsche to work with a supplier to develop a new type of brake pad (which Porsche says don’t cost any more than recommended pads for the carbon ceramic rotors), since regular pads couldn’t properly grip the surface. The result is a brake system that allegedly has a 30 percent higher service life than its standard gray cast iron counterpart. And, perhaps more interestingly, Porsche says PSCB’s friction value is less affected by rotor temperature than a standard uncoated iron disc.

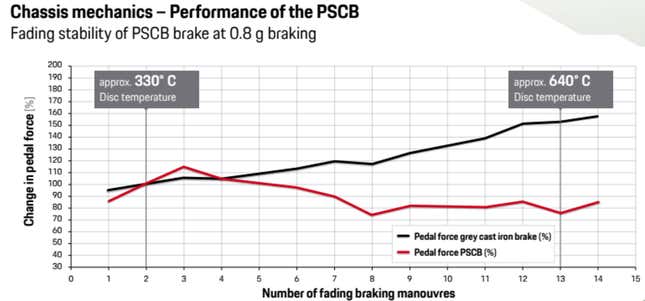

The plot above shows pedal force as a function of fading brake maneuvers. At the end, the discs have both reached 640 C, and you can see that at that temperature, brake pedal force for the standard rotor has increased, whereas the new pad material clamping the coated rotor yielded very little change in pedal force required to achieve the same negative acceleration. Porsche’s engineer said temperatures above 700C are when PSCB starts to see significant changes in pedal force.

The new brake rotor—which is made in a process involving pre-treating, thermal structuring, galvanizing, and coating—comes as part of a $3,490 brake package. That package gets you a nice set of 16.3-inch rotors up front and 14.3-inchers out back, all clamped by white 10-piston calipers that, after a few hundred miles of normal driving, will yield a beautiful reflective, rust-resistant rotor surface like this one:

So basically, these are large, super-hard rotors clamped by giant calipers outfitted with special brake pads. That allegedly means less brake dust, less pedal effort at the track, higher corrosion resistance, and a longer service life. Sounds good in theory.

Off-Road

Of course, we all wonder how the Porsche Cayenne does off-road, especially since it’s lost some of the hard-core attributes of its predecessors, namely a low-range transfer case and great approach and departure angles.

But the 2019 is still no slouch; it has a nice and short 5:1 first gear ratio (only about a 3:1 diff ratio, though), engine options with plenty of low-end torque, an electronically-controlled rear locker, a clutch-based transfer case that can send power where it’s needed, a sway bar system that can maximize flex, and optional skid plates to keep the important bits intact. Plus, the 27.1/24/21 degree approach/breakover/departure angles aren’t that terrible, either.

As you can see in the video below, even with summer tires, the Cayenne can climb some impressive slopes.

New Transmission and Transfer Case

I also got a close up look at Porsche’s eight-speed Tiptronic S, which has an integrated front differential and driveshaft (similar to some ZF eight-speed all-wheel drive setups). This trans has an 884 lb-ft torque capacity, apparently quicker shift times, and new sun gear and planet gear sets that yield a wider gear spread than the last generation transmission.

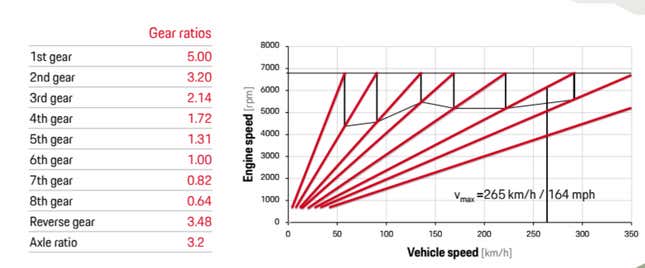

Porsche calls it a “6+2 configuration,” in that two of the eight gears are overdrives (top speed is achieved in sixth). First gear, at 5:1, is shorter than last year’s model, which theoretically means better acceleration and off-road crawl-ability. And eighth gear, at 0.64:1, is taller than the outgoing transmission, which is good for highway fuel economy. Total gear spread on non-turbo models is 7.8; you can see all gear ratios below below:

Porsche engineers say they’ve reduced churning losses by separating clutch plates using small coil springs, and by using a chain-driven eccentric-vane oil pump instead of a concentric style. In addition, they say the torque converter torque ratio has been increased, which helps increase low-speed response.

The transmission’s shift-by-wire setup is new, and the monostable shifter lever throws are now shorter. In addition, autostart/stop doesn’t wait until the car has come to a halt, but can actually shut the engine off even as the car coasts at speeds up to 4 mph. That autostart/stop functionality, like on other vehicles with the technology, is aided by an electric trans fluid pump, which makes sure the transmission’s fluid pressure-activated shift elements receive pumped automatic transmission fluid even when the engine is not running.

That transmission sends torque through an electronically-controlled wet clutch-based transfer case called “Hang-on All-Wheel Drive,” which always sends power to the rear axle, but apportions up to 100 percent of the torque to the front based on driving conditions and driving mode.

Porsche engineers say the all-wheel drive system has a torque capacity of 1,032 lb-ft, and that the system actively helps the car rotate by strategically apportioning torque between the front and rear tires (which are now staggered on the new Cayenne for better driving dynamics—255, 275 or 285 section up front; 275, 305 or 315 section out back).

How does all this work in practice? Well, I didn’t get to drive the car, so I can’t tell you much. But what I can tell you is that the Cayenne can drift. My god can it drift:

For a vehicle that weighs nearly 4,500 pounds, it sure seems happy to hang its rear end out there without toppling into a ditch.

Engines

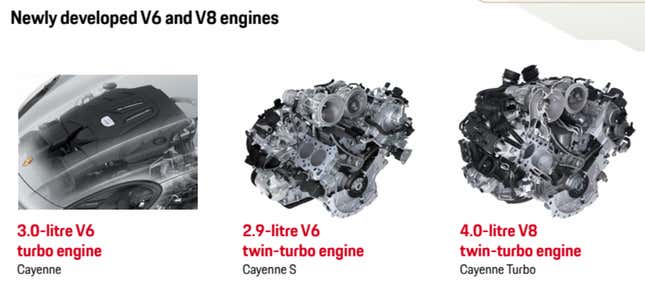

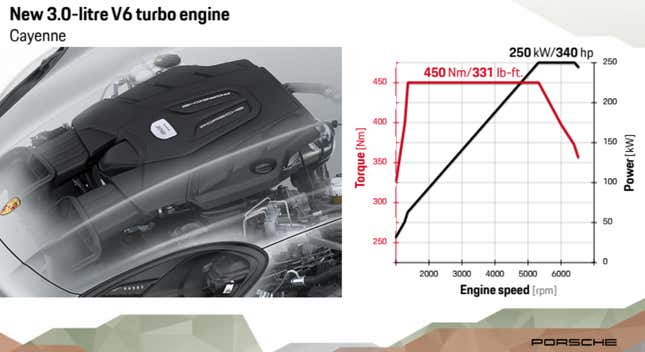

On the powertrain front, the Cayenne has a new range of engines that includes a 3.0-liter turbo V6 making 340 horsepower and 331 lb-ft of torque—those are improvements of 40 HP and 31 lb-ft over the predecessor, respectively.

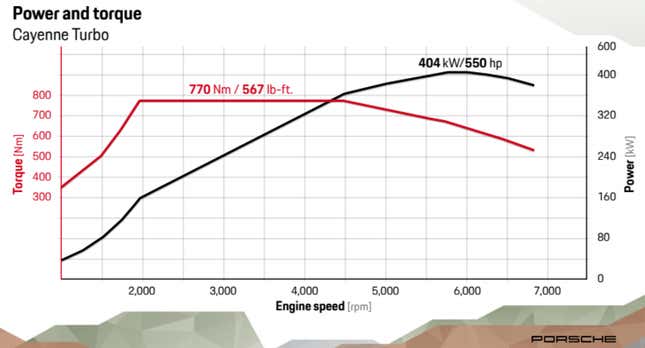

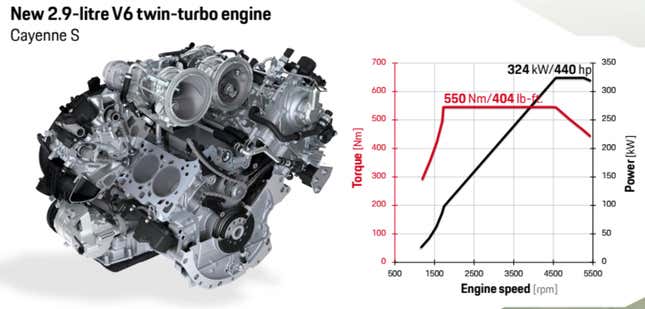

Next up on the Cayenne S model comes a 2.9-liter twin-turbo V6 that pumps out 20 more horsepower than its predecessor (for a total of 440) and 404 lb-ft of torque. And then there’s the 550 horsepower (up 30 HP), 567 lb-ft (up 14 lb-ft) bruiser 4.0-liter V8 in the Cayenne Turbo.

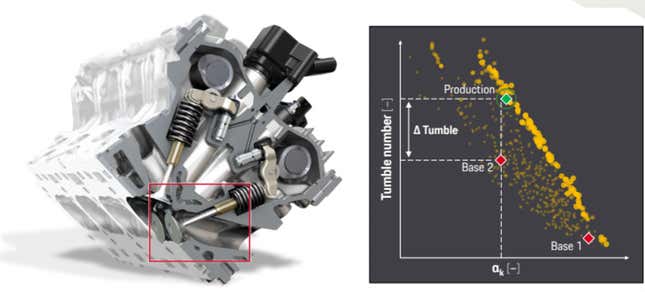

Among improvements to the engines is the placement of the turbochargers into the V, as shown in the top image of this section. This not only provides a packaging benefit, allowing the engine to theoretically be placed lower in the car, but it also shortens the exhaust path between the exhaust valve and the turbocharger turbine wheel, which means less turbo lag.

The turbos are also twin-scroll, meaning exhaust gas pulses leaving one cylinder won’t adversely affect those leaving another (i.e. they won’t have a negative effect on exhaust scavenging), which Porsche says is an efficiency benefit.

Porsche was especially proud of the strides it made with its 4.0-liter V8. Engineers touted the fact that the crankcase now weigh’s 15 pounds less than its predecessor thanks to a new manufacturing technique. The whole block is now more rigid thanks to “high-strength, quadruple-bolted main bearing covers.” And there’s a new plasma-sprayed cylinder coating with different 150 micron layers that promise less oil consumption and wear.

In addition, the company boasted about the V8's 3,625 psi centrally-located fuel injectors, and a cylinder head whose intake port has been optimized to maximize airflow and ensure lots of tumble—a term that describes the turbulent airflow in the cylinders that’s so important in maximizing burn rate and combustion efficiency.

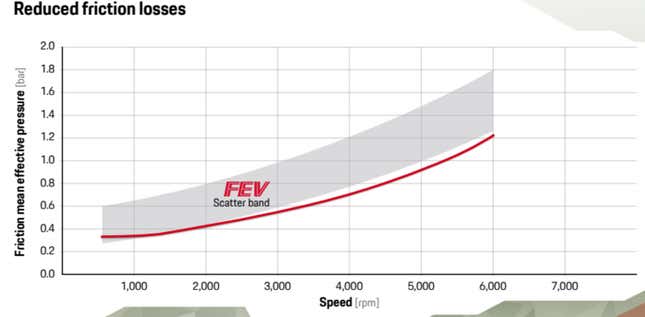

On top of that, Porsche says it used special oil spray nozzles, optimized crankcase ventilation system, a switchable water pump (so as to match pump output with cooling system demands), an electric water pump, low friction oils, and the previously-mentioned cylinder liner to reduce engine friction. The plot below, created by engineering consultancy FEV, shows how the new 4.0-liter V8's friction mean effective pressure compares with a scatter band comprised of the competition.

Obviously, it’s worth mentioning that we don’t know how that “scatter band” was generated, or which engines it includes, but the point is: the V8 apparently wastes less energy overcoming friction than its predecessor.

And because mentioning the engines with the the torque curves would be absurd, here they are, starting with the Cayenne Turbo:

Next is the torque curve for the the Cayenne S:

And finally, the base model:

Body

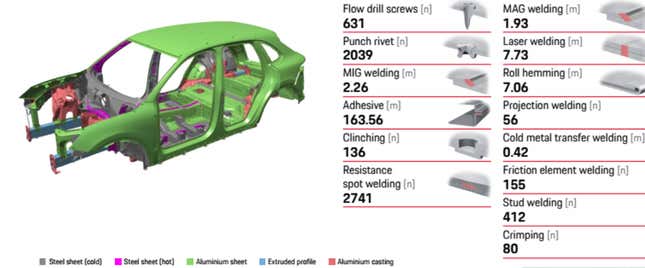

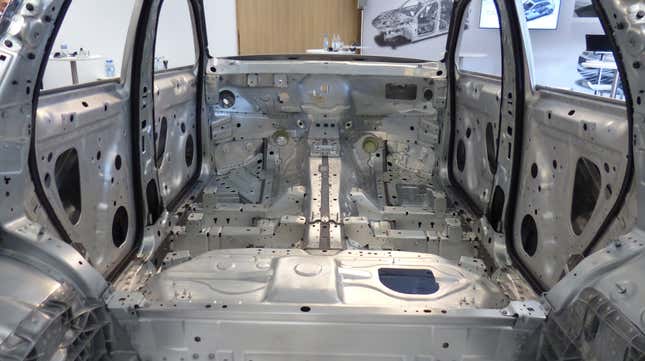

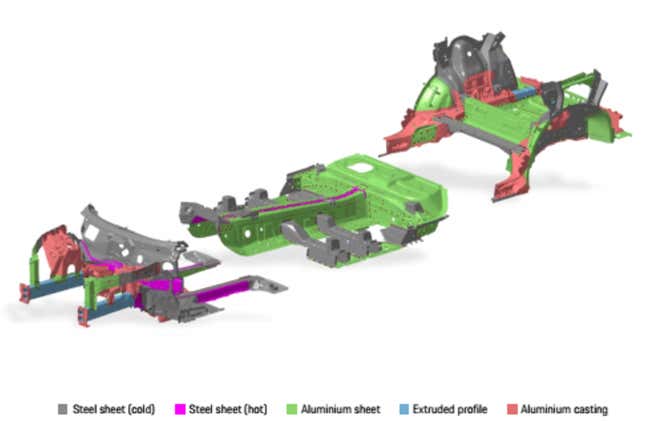

The final class Porsche put me in dealt with the new Cayenne’s body, whose complete outer shell is made of aluminum—this includes the hood, roof, floorpan, doors, and rear hatch, and a lot more, as you can see in the image below.

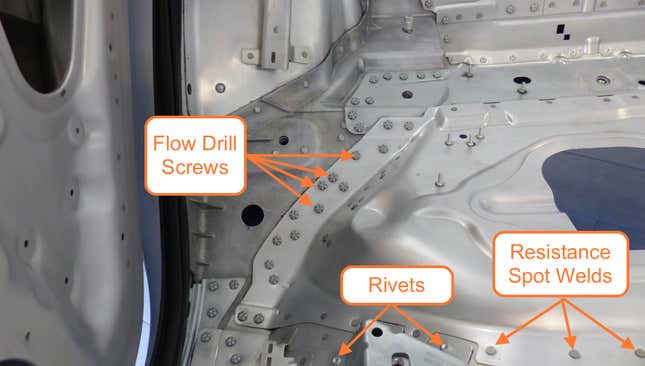

The photo above also shows the many fastening and joining methods Porsche used to put the car together. Just look at all the welds, rivets and screws in this interior:

Here’s an image showing a few of those joining processes up close:

And if you’re looking for some laser weld action, here you go:

And here are a couple of clinch spots under the rear light:

Forty-two percent of the new Cayenne’s body is made of conventional sheet steel, 31 percent is of aluminum sheet, 13 percent is aluminum casting, 11 percent is hot formed steel, and 3 percent is extruded aluminum. Here’s a look at the material breakdown of the platform without the upper shell attached:

Overall, despite the additional crash safety provisions and other features on the new Cayenne, the vehicle weighs up to 143 pounds less than its predecessor, in part because of smart weight-savings like a lithium-ion starter battery, and in part because of the clever uses of aluminum on the new body.

Aerodynamics

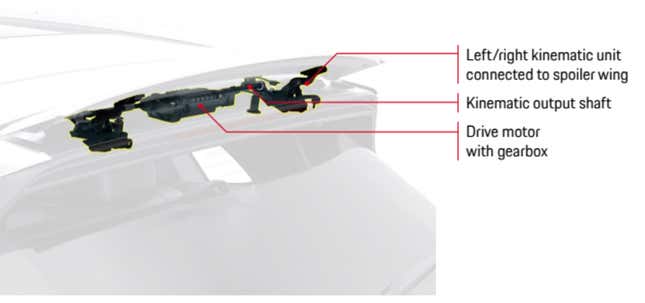

The body “class” also included some words from aerodynamics manager Thomas Wolf, who began by talking about the most obvious bit of aerodynamic goodness on the new Cayenne: the rear wing. He told us that under high speed driving conditions over about 100 mph, the wing will rise to a six degree angle to keep the rear of the car stable. Sport Plus mode brings that angle to 12.6 degrees for additional downforce, and if the panoramic sunroof is open, the wing will increase further to 19.9 degrees to compensate for the turbulence.

Over about 124 mph, the wing retracts to reduce drag at high speeds (since you’re likely not making sharp turns at that speed anyhow), and extends again when the speed drops below 112 mph.

When the driver hits the brake hard while traveling between 106 mph and 168 mph, the wing—which consists of an electric motor mated to a gearbox—rises to 28.2 degrees, acting as an airbrake. Porsche says the brake can reduce stopping distances by over 6.5 feet from 155 mph.

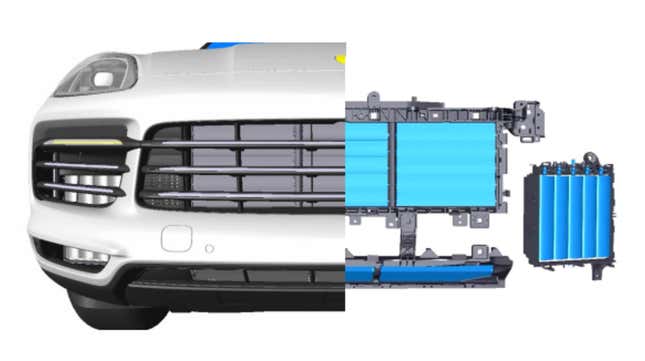

Though the wing gets all the credit, arguably the more interesting bits of aero are up front, especially the active grille shutters. Porsche says the Cayenne is the first vehicle with 100 percent adjustable closure of all heat exchangers.

As you can see below, AGS covers the top, lower, and remote-mounted heat exchangers (the later of which are the much-less-common vertical grille shutters). These four systems can be controlled independently, and are infinitely adjustable (i.e. stepless).

What this means is that, depending upon the cooling needs of the powertrain, drivetrain, and cabin, the vehicle can let in more airflow into certain heat exchangers. The benefit is that keeping the shutters closed longer diverts air around the body instead of through a rather tortuous, aerodynamically inefficient engine bay.

In addition, as you can see in the image at the top of this section, after air passes through the remote-mounted charge air coolers, an “air curtain” accelerates it out of the wheel wells, minimizing turbulence created by the wheels, and reducing drag. In addition, there’s also a very flat underbody for drag reduction, and plastic scoops on the front suspension to divert air to the brakes:

So that’s all the cool stuff I learned at the Porsche Cayenne Technology Workshop. Some of it is unique to the Cayenne, some of it you’ll see on a number of competitive vehicles, and quite a lot of it can be found on the Audi Q7 or Porsche Panamera.

Regardless, it was all surprisingly fascinating, but we’ll see how it all comes together when Jalopnik test drives the new Cayenne later this month.

Correction: Per the video in the article, the rear steering system uses a trapezoidal power screw, not a ball screw as previously written.